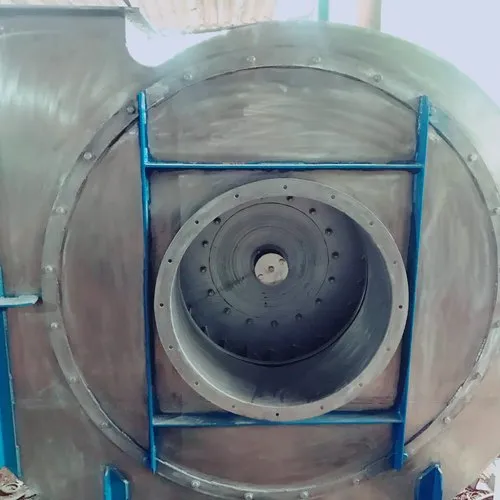

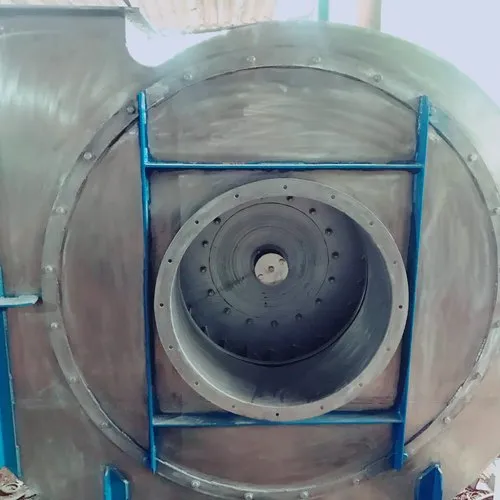

Stainless Steel Blower

Home / Products / Centrifugal Blower / Stainless Steel Blower

Stainless Steel Blower Manufacturer

When it comes to stainless steel blowers, there are several options available from different manufacturers, each with its own set of features and specifications. These blowers are commonly used in industries where corrosion resistance, hygiene, and durability are crucial. Here’s a breakdown of some key aspects to consider when looking for a stainless steel blower:

Material Quality

Ensure that the blower is made from high-quality stainless steel, typically grade 304 or 316, which offers excellent corrosion resistance and durability, especially in harsh environments.

Design

Look for a blower with a robust and corrosion-resistant design, including stainless steel housing, impeller, shaft, and other critical components. The design should facilitate easy cleaning and maintenance.

Performance

Consider the airflow capacity, static pressure capabilities, and efficiency of the blower. Depending on your specific application, you may need a blower with variable speed control options to adjust airflow as needed.

Motor

Choose a blower with a high-quality motor suitable for your application’s requirements, ensuring reliable performance and energy efficiency. Variable frequency drives (VFDs) can be beneficial for controlling motor speed and reducing energy consumption.

Application Specifics

Consider the specific requirements of your application, such as the environment (e.g., corrosive chemicals, high temperatures), airflow volume, noise level restrictions, and any industry regulations or standards that need to be met.

Customization Options

If your application requires customizations or special features, such as specific mounting arrangements, inlet configurations, or explosion-proof designs, ensure that the manufacturer can accommodate your needs.