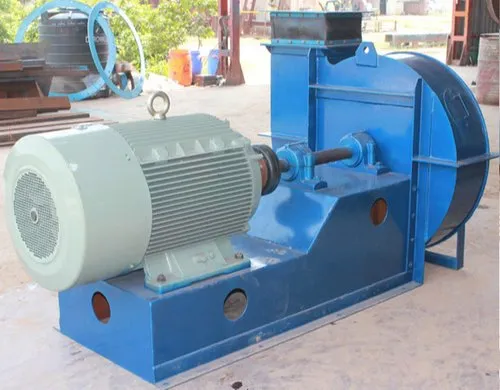

Direct Coupling Type Blower

Home / Products / Centrifugal Blower / Direct Coupling Type Blower

Direct Coupling Type Blower Manufacturer

A direct-coupling type blower, also known as a direct-drive blower, is a type of air-moving device where the blower’s impeller is directly connected to the motor shaft without any intermediary components such as belts or pulleys. Here’s an overview of direct-coupling type blowers, including their features, applications, and considerations:

Features of Direct Coupling Type Blowers

- Direct Connection: The impeller of the blower is directly connected to the motor shaft, eliminating the need for belts, pulleys, or couplings. This direct connection results in a more compact and efficient design.

- Simplified Maintenance: Since there are no belts or pulleys to maintain or replace, direct-drive blowers often have simplified maintenance requirements, leading to reduced downtime and lower maintenance costs.

- Efficiency: Direct-coupling type blowers can be more efficient compared to belt-driven blowers because they eliminate energy losses associated with belt slippage or friction.

- Space Saving: The absence of belts and pulleys reduces the overall footprint of the blower, making it suitable for applications where space is limited.

- High-Speed Operation: Direct-drive blowers typically operate at higher speeds compared to belt-driven blowers, which can be advantageous in applications requiring high airflow rates or where space constraints limit the size of the blower.

- Reduced Noise and Vibration: Direct-drive blowers may produce less noise and vibration compared to belt-driven blowers since there are fewer moving parts and potential sources of vibration.

Applications

- HVAC Systems: Direct-drive blowers are commonly used in heating, ventilation, and air conditioning (HVAC) systems for residential, commercial, and industrial applications.

- Cleanrooms and Laboratories: They are utilized in cleanroom environments and laboratories where precise airflow control and minimal contamination are essential.

- Industrial Ventilation: Direct-drive blowers find applications in industrial ventilation systems for air circulation, exhaust, and fume extraction in manufacturing facilities.

- Food Processing: In the food processing industry, direct-drive blowers are used for applications such as drying, cooling, and conveying food products.

- Agriculture: They are employed in agricultural settings for ventilation in livestock buildings, crop drying, and grain aeration.

- Material Handling: Direct-drive blowers can be used in pneumatic conveying systems for transporting materials such as powders, granules, and pellets.

Considerations

- Motor Selection: Choosing the appropriate motor for the blower is crucial to ensure reliable performance and efficiency. Factors to consider include motor power, speed, and compatibility with the blower's operating conditions.

- System Design: Proper system design is essential to ensure that the direct-drive blower operates efficiently and meets the airflow requirements of the application.

- Maintenance: While direct-drive blowers may have simplified maintenance requirements compared to belt-driven blowers, regular inspection and lubrication of bearings and motor components are still necessary to ensure optimal performance and longevity.

- Cost: Direct-drive blowers may have higher initial costs compared to belt-driven blowers, but they can offer long-term cost savings due to lower maintenance requirements and higher efficiency.