Pharma Air Handling Unit

Home / Products / Air Handling Units (AHU) Manufacturer In India / Pharma Air Handling Unit

Pharma Air Handling Unit Manufacturer

In pharmaceutical facilities, maintaining precise environmental conditions is crucial to ensure product quality, regulatory compliance, and the safety of personnel. A pharmaceutical air handling unit (AHU) is a specialized HVAC system designed to meet the stringent requirements of pharmaceutical manufacturing, research, and storage environments. Here’s a closer look at its function and construction:

Pharma Air Handling Unit

Function of Pharma Air Handling Unit

- Temperature and Humidity Control: Pharmaceutical AHUs are equipped with precise temperature and humidity control systems to maintain stable environmental conditions within manufacturing areas, laboratories, and cleanrooms. This helps to ensure the integrity and stability of pharmaceutical products and raw materials.

- Clean Air Delivery: AHUs in pharmaceutical facilities are designed to deliver clean, filtered air to critical areas where sterile or controlled environments are required. High-efficiency particulate air (HEPA) filters and ultra-low particulate air (ULPA) filters are often used to remove airborne contaminants and maintain air purity.

- Pressure Control: Pharmaceutical AHUs may incorporate pressure control systems to establish positive or negative pressure differentials between adjacent spaces, such as cleanrooms, laboratories, and corridors. Positive pressure prevents the ingress of contaminants, while negative pressure helps to contain hazardous materials and prevent their escape into surrounding areas.

- Air Filtration: Advanced filtration systems are employed in pharmaceutical AHUs to remove particles, microbes, and other contaminants from the air. In addition to HEPA and ULPA filters, AHUs may include pre-filters, medium filters, and carbon filters to achieve the desired level of air cleanliness.

- Ventilation: Proper ventilation is essential in pharmaceutical facilities to ensure adequate air exchange rates and prevent the buildup of airborne pollutants and gases. Pharmaceutical AHUs are designed to provide sufficient ventilation while maintaining controlled environmental conditions.

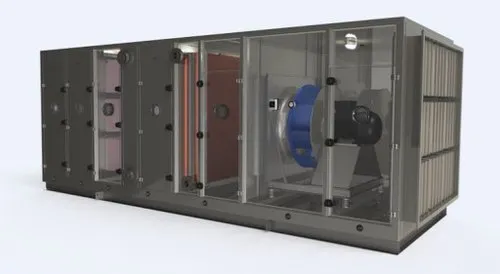

Construction of Pharma Air Handling Unit

- Fan and Motor: Pharmaceutical AHUs are equipped with high-quality fans and motors capable of delivering the required airflow rates and static pressures. Variable frequency drives (VFDs) may be used to modulate fan speed and optimize energy efficiency.

- Filters: HEPA filters and ULPA filters are the cornerstone of pharmaceutical AHUs, providing high-efficiency air filtration to remove particles down to submicron sizes. These filters are housed in filter banks or filter housings designed to maintain filter integrity and prevent bypass leakage.

- Coils and Heat Exchangers: AHUs include coils or heat exchangers for heating and cooling air as necessary to achieve the desired temperature conditions. These components are typically constructed of corrosion-resistant materials to withstand the harsh operating environments of pharmaceutical facilities.

- Control Systems: Pharmaceutical AHUs are equipped with advanced control systems that monitor and regulate various parameters such as temperature, humidity, pressure differentials, and airflow rates. These control systems ensure precise control over environmental conditions and facilitate compliance with regulatory requirements.

- Materials and Finishes: AHU components are constructed of durable materials such as stainless steel, aluminum, or coated steel to withstand frequent cleaning and disinfection procedures. Smooth surfaces and seamless construction minimize the risk of microbial growth and facilitate cleaning and maintenance.

- Insulation and Seals: AHUs are insulated to prevent condensation and minimize thermal losses or gains. Seals and gaskets are used to ensure airtight construction and prevent air leakage, maintaining the integrity of controlled environments.

Applications of Pharma Air Handling Unit

Pharmaceutical air handling units (AHUs) have diverse applications within pharmaceutical manufacturing, research, and storage facilities. Here are some key applications:

- Cleanrooms: Cleanrooms are essential in pharmaceutical manufacturing to ensure product quality by minimizing contamination risks. Pharmaceutical AHUs are used to maintain the required cleanliness levels by delivering filtered and conditioned air to cleanroom environments. These AHUs provide precise control over temperature, humidity, and pressure differentials to meet stringent cleanroom standards, such as ISO classes 5 to 9.

- Sterile Manufacturing Areas: Pharmaceutical AHUs play a critical role in maintaining sterile manufacturing environments for the production of injectable drugs, sterile solutions, and biologics. These AHUs deliver high-efficiency particulate air (HEPA)-filtered air to sterile processing areas, preventing microbial contamination and ensuring product sterility.

- Laboratories: Pharmaceutical research and development laboratories require controlled environments to conduct experiments, testing, and analysis. Pharmaceutical AHUs provide clean and stable air to laboratory spaces, helping to protect sensitive equipment and samples from contamination and maintaining consistent environmental conditions for accurate results.

- API Manufacturing: Active pharmaceutical ingredient (API) manufacturing facilities require controlled environments to ensure product purity and consistency. Pharmaceutical AHUs are used to provide clean and conditioned air to API production areas, minimizing the risk of cross-contamination and maintaining regulatory compliance.

- Packaging and Labeling Areas: Pharmaceutical AHUs are employed in packaging and labeling areas to maintain clean and controlled environments for secondary packaging operations. These AHUs help to protect finished products from contamination during the final stages of production and ensure compliance with good manufacturing practices (GMP).

- Warehousing and Storage: Pharmaceutical warehouses and storage areas require controlled environments to preserve product quality and stability. Pharmaceutical AHUs provide conditioned air to storage facilities, helping to control temperature, humidity, and air quality to prevent degradation and ensure the integrity of stored products.

- Quality Control and QC Laboratories: Quality control (QC) laboratories perform testing and analysis to verify the quality, purity, and potency of pharmaceutical products. Pharmaceutical AHUs maintain clean and stable air in QC laboratory spaces, minimizing the risk of sample contamination and ensuring accurate test results.

- API Dispensing and Weighing Rooms: Pharmaceutical AHUs are used in API dispensing and weighing rooms to provide clean and controlled environments for the handling of raw materials and intermediates. These AHUs help to prevent cross-contamination and maintain product integrity during the dispensing and weighing process.