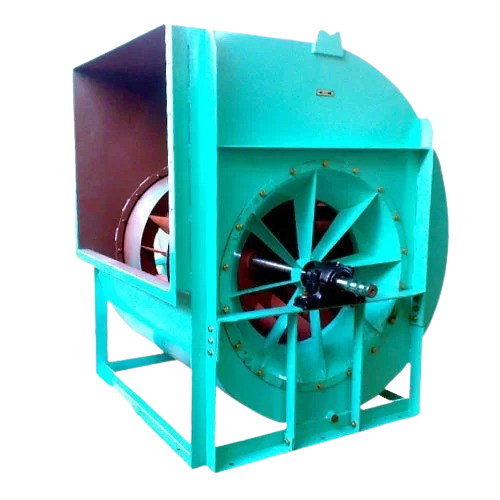

Limit Load Blower

Home / Products / Centrifugal Blower / Limit Load Blower

Limit Load Blower Manufacturer

A limit load blower, also known as a high-pressure blower, is a type of air-moving device designed to generate significant air pressure to overcome high resistance or static pressure within a system. Here’s an overview of limit load blowers, including their features, applications, and considerations:

Features of Limit Load Blower

- High Pressure Output: Limit load blowers are capable of generating high air pressures, typically ranging from several inches of water column (inWC) to several pounds per square inch (psi).

- Robust Construction: They are built with sturdy materials and robust construction to withstand the higher pressures and harsh operating conditions.

- Efficient Impellers: Limit load blowers often feature specially designed impellers that can efficiently move air against high resistance, such as in ductwork, filters, or other obstructions.

- Powerful Motors: They are equipped with powerful motors to drive the impellers and maintain the desired air pressure, even under varying load conditions.

- Sealing Mechanisms: Effective sealing mechanisms, such as labyrinth seals or mechanical seals, are employed to prevent air leakage and ensure efficient operation.

- Variable Speed Control: Some limit load blowers offer variable speed control options to adjust airflow and pressure according to the specific requirements of the application, providing energy savings and enhanced control.

Applications

- Industrial Ventilation: Limit load blowers are used in industrial ventilation systems to provide airflow for processes such as drying, cooling, and exhaust ventilation in manufacturing facilities.

- Pneumatic Conveying: They are employed in pneumatic conveying systems to transport materials such as powders, grains, and granules through pipelines or ducts, overcoming high resistance and maintaining consistent flow rates.

- Air Pollution Control: Limit load blowers play a crucial role in air pollution control systems, such as baghouses, scrubbers, and electrostatic precipitators, by providing the necessary airflow for capturing and removing pollutants from the air stream.

- Material Handling: They are utilized in applications such as aeration, agitation, and fluidization in material handling processes, including bulk material storage, mixing, and conveying.

- HVAC Systems: Limit load blowers may be incorporated into HVAC systems for pressurizing ductwork, supplying air to critical areas, or overcoming high static pressure losses in large commercial or industrial buildings.

- Wastewater Treatment: In wastewater treatment plants, limit load blowers are used for aeration in aerobic digestion processes and providing airflow to biological treatment systems, overcoming high resistance from diffusers or submerged aerators.

Considerations

- System Design: Proper system design is essential to ensure that the limit load blower operates efficiently and meets the desired performance requirements, taking into account factors such as ductwork layout, resistance, and airflow distribution.

- Material Compatibility: Consider the compatibility of materials with the handled air or gas stream to prevent corrosion or damage to blower components, especially in corrosive or abrasive environments.

- Noise Levels: Limit load blowers can produce significant noise levels, so noise reduction measures may be necessary, such as sound enclosures or silencers, to comply with occupational health and safety regulations.

- Maintenance: Regular maintenance is crucial to ensure the reliable operation of limit load blowers, including inspection, lubrication, and replacement of worn components, to prevent downtime and costly repairs.

- Energy Efficiency: Selecting energy-efficient blowers and optimizing system operation can help reduce energy consumption and operating costs, especially in applications with variable airflow requirements.